Altium Plated Slots

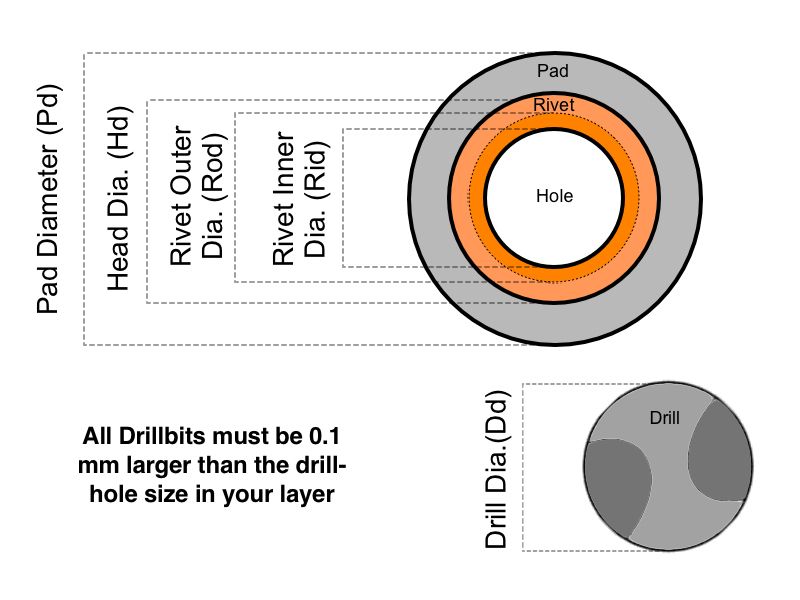

The battery terminal tabs should come up through slots in the PCB, and solder to a pad around the slot perimeter. I created a new connector in our parts library as a through-hole with the dimensions of the slot I need. The three choices for hole types are 'round', 'rectangle', and 'slot'. The slots are done in a different step than the via drilling. $ endgroup $ – Some Hardware Guy Dec 14 '12 at 3:13 $ begingroup $ Humm ok.I just feel unconfortable with so many different ways to interpret a PCB and repesent a slot.and OSH Park dont show them, unless you put it on the board edge layer I think $ endgroup $ – mFeinstein. This is best shown with a Drill Table and produced with an NC Drill File. (Check hole sizes with Panels/PCB/Hole Size Editor.) Number of different hole sizes. These should be in increments of 2 mils (0.05mm) for consistent, cost effective results. Definitions for Plated, Non-Plated, and depth (Blind, Buried, and back drilled.

The footprint on the left in this image clearly leaves much more empty space around the component leads, where the image on the right provides a snug fit. This makes the circular hole configuration much more prone to common PCB Assembly defects such as solder joint voiding, since more solder is required to fill the holes.

These concerns become more significant as the size of the pins increases, from both design and production perspectives, so large blade-style connectors should definitely use plated slots rather than circular holes. At Bittele, we can still work with circular holes for rectangular pins when the part is relatively small, such as the standard barrel power connector used in this example. That being said, the circular holes do also take up more space on the PCB itself, and using plated slots can often help in size-restricted designs.

For the design of non-circular holes, a few things must be considered, but the process is fairly straightforward overall. It should first be noted that slots can be defined as plated through holes (PTH) or non-plated through-holes (NPTH). PTH slots are most often used in component footprints, and most PCB layout CAD programs provide an option in their footprint editor to define a hole as circular or oval. This will be enough for Bittele’s PCB Fabrication team to recognize the hole and use the correct process, but for extra clarity, some clients also indicate slot holes on a fabrication layer of their Gerber files.

NPTH Slots can be designed in the same manner, and simply designated as NPTH / Mechanical in the CAD software, or they can be designed on the Board Outline Gerber layer. The following images show multiple options for both PTH and NPTH slots, first in a Gerber file view and then a 3D rendering of the resulting board.

If you have a question about hole shapes or sizes in your design, please feel free to Contact Us at any time and ask one of our PCB experts. With our flexible PCB Fabrication process at your disposal, never again will you need to fit a square peg in a round hole.

Altium Plated Slots Game

Related Articles:

Altium Plated Slots Coins

Search articles: